Rubber tubing moves liquid and gasses in hydraulic, pneumatic, medical, and industrial processes. The rubber tubings are flexible and sturdy. Rubber tubings are formed using natural and synthetic rubbers. Manufacturers can convert the latex of natural rubber into rubber tubing. Synthetic rubbers are artificial rubbers. Read More…

As the largest in-house pure gum inventory carrier in the U.S., Atlantic Rubber Company has cost-effective and resilient rubber tubing. We carry a variety of materials so that we can make the best product for your needs.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber is your source for extruded, Molded, Die cut & Secondary fabrication work in rubber products, tubing and shapes made out of Silicone, Flurosilicone, Viton, Nitrile, Neoprene, EPDM, SBR,butyl & any custom compound. We offer our customers high quality, complex shapes and fast turn-around times.

Established in 1986, GSH Industries supplies plastic, aluminum and rubber tubing to an array of industries including automotive, consumer, marine and electrical.

More Black Rubber Tubing Manufacturers

Materials Used

Rubber tubings are differentiated by rubber-based materials used in their production. Black rubber tubing is made by adding black color to natural or synthetic rubber. The rubber material is known for its elasticity, flexibility, tear resistance, stretch, and thermal stability up to certain temperatures. There are many types of synthetic rubbers used for black tubing production. These are as follows:

Butyl Rubber

Butyl rubber material has excellent chemical, ozone, heat resistance, and low gas permeability.

Isoprene

Isoprene is a fat-free derivative of natural rubber with high abrasion resistance.

Nitrile Rubber

Nitrile rubber has high wear, chemical, and temperature resistance. It is also highly resilient.

Polychloroprene

Polychloroprene is an ozone, heat, and oil-resistant synthetic material.

Styrene-Butadiene

Styrene-Butadiene is an inexpensive material with good tensile strength, flexibility, and heat resistance. This material is also inexpensive.

Characteristics of Black Rubber Tubing

The following are the characteristics of black rubber tubing:

- Black neoprene rubber tubing is made of high-quality, flexible materials.

- It has a high-temperature range and is also highly durable.

- Black rubber tubing has good abrasion, weather, and aging resistance.

- Black rubber tubing is easy to cut and available in a wide range of diameters according to its application.

- Black rubber tubing is a good option for transferring a wide range of liquids, including oil-based liquids.

- Black rubber tubings are highly flexible and are therefore used in corners and tight surfaces for transferring liquids.

- Black rubber tubings are good conductors of electricity, so they are not recommended for electrical environments.

- Black rubber tubings are non-resistant to easter lubricants, so they aren’t best for refrigerators.

Manufacturing of Black Rubber Tubing

As discussed earlier black rubber tubing is made from natural and synthetic rubber. The latex or sap released from natural rubber is used to manufacture black rubber tubing. The latex is mixed with water and other chemicals to thicken its texture. When it is thickened to the desired level, black dye is added.

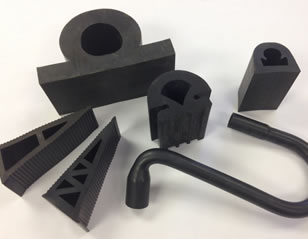

Black rubber tubing can be manufactured through an extrusion process or a mandrel process.

Extrusion Process

In the extrusion process, the raw, unvulcanized black rubber is fed to the extruder, then put into the die. The amount of temperature and pressure applied depends on the type of tubing being produced. Sulfur is used for its vulcanization.

Mandrel Process

In mandrel process, the rolls or mandrel are dipped into the black rubber material. Then they are heated or vulcanized to be made inelastic and stiff. This process can create Vehicle tires and shoe soles.

Applications of Black Rubber Tubing

- Black rubber tubing is the best option in corners, small spaces, and whenever it’s best to hide the tubing.

- Black rubber tubing is best for the absorption and retention of heat; therefore, it’s often used as an insulator. It’s used in pond filters to reduce the chance of water freezing.

- Black rubber tubings are widely used in the automotive industry, households, and laboratories to protect pipes and tubes and to transfer liquids and gases.

- Black rubber tubings are also used in schools, laboratories, outdoors, and in water taps for the safe transfer of liquids and diluted acids.

Choosing the Right Black Rubber Tubing Manufacturer

To make sure you have the most beneficial outcome when purchasing black rubber tubing from a black rubber tubing manufacturer, it is important to compare at least 4 manufacturers using our black rubber tubing directory. Each black rubber tubing manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each black rubber tubing business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple black rubber tubing businesses with the same quote.

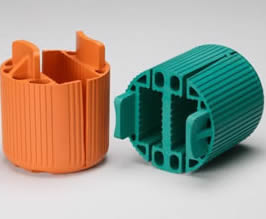

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

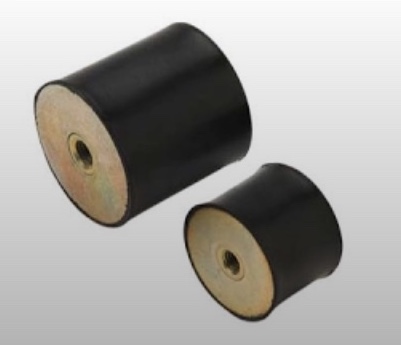

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services