More Rubber Tubing Manufacturers

The History of Rubber Tubing

Rubber tubing, a pivotal component in countless industries, has a rich history dating back to the 1800s. Its journey began in the mid-1800s, when early inventors developed rubber tympanostomy tubes to relieve fluid accumulation in the middle ear. Noteworthy examples include Lincke’s rubber tube and Ádám Politzer’s hard rubber drain—precursors to modern medical tubing.

The earliest rubber tubing was crafted from pure gum rubber, also known as natural rubber. For many decades, latex tubing dominated the market, prized for its elasticity and chemical resistance. However, with the rise of latex allergies in the 1980s, especially among healthcare professionals, manufacturers responded by developing alternative materials such as nitrile, neoprene, and silicone for tubing and gloves, dramatically expanding the options for end-users in medical, laboratory, and industrial environments.

Even before widespread concerns about latex allergies, the drive for innovation led to the creation of synthetic rubbers. In 1909, Bayer scientists produced the first viable synthetic rubber, opening the door to more durable, cost-effective products for the burgeoning automotive industry. Synthetic rubber tubing—including butyl rubber—became especially significant during World Wars I and II, when natural rubber supplies were constrained. These synthetic materials expanded the application spectrum of rubber tubing to sectors like defense, aerospace, and high-performance manufacturing.

The evolution of rubber tubing continued in 1957 when DuPont (formerly E.I. du Pont de Nemours & Company) introduced Viton—a fluoroelastomer with unmatched chemical resistance, temperature flexibility, and durability. This material revolutionized aerospace tubing and set new benchmarks for chemical processing, automotive, and industrial applications.

Today, rubber tubing is available in countless configurations. Modern rubber tubing manufacturers offer an extensive range of shapes, sizes, wall thicknesses, and materials, including advanced elastomers and specialty compounds. This versatility allows designers, engineers, and procurement professionals to source tubing for virtually any scenario—from peristaltic pump tubing in laboratories to abrasion-resistant hoses in mining and construction.

Rubber Tubing Production Process

Rubber tubing is crafted through a complex, quality-driven manufacturing process that transforms raw materials into high-performance, application-specific products. Whether the tubing is destined for medical, automotive, food processing, or industrial use, understanding how it is made helps buyers make informed choices. Key rubber tubing materials include natural latex, neoprene, silicone, vinyl (PVC), EPDM, and Viton, each offering unique characteristics to suit different operating environments.

Material Preparation

The process begins with material selection and preparation. Natural rubber is harvested from the Pará rubber tree (Hevea brasiliensis) or other latex-producing plants using a tapping method similar to maple syrup collection. The raw latex is then mixed with additives—such as stabilizers, pigments, or curing agents—to enhance properties like flexibility, resilience, color, and chemical resistance. Vulcanization, a critical step, involves heating latex with sulfur to strengthen the rubber and improve its elasticity, durability, and resistance to heat and chemicals.

For synthetic rubber tubing, manufacturers blend chemicals and polymers using advanced formulation and mixing techniques. This allows them to design custom rubber compounds tailored for specific requirements—such as flame resistance, UV stability, or inertness for sensitive fluids—making it possible to engineer tubing for critical or niche applications.

Extrusion

The core of rubber tubing production is the extrusion process. In extrusion, uncured rubber is fed into an extruder—a specialized machine that forces the material through a precisely shaped die. This process creates tubing with highly consistent outer diameters (OD), inner diameters (ID), and wall thicknesses, critical for ensuring reliable performance in fluid transfer, pneumatic, and vacuum applications.

Secondary Processing

After extrusion, rubber tubing often undergoes secondary processes to enhance its properties and appearance. These include curing (via heat or chemical baths) to set the rubber, precision cutting to length, surface treatments (such as coatings for chemical or UV resistance), drilling, custom labeling, and even assembly with connectors or fittings. These finishing steps are vital for meeting industry-specific standards—such as FDA, USP Class VI, or NSF compliance in medical and food-grade tubing.

Considerations and Customization

When designing and specifying rubber tubing, manufacturers and buyers must consider multiple factors: operating environment (exposure to temperature extremes, chemicals, UV radiation, or pressure), fluid compatibility, required flexibility, and regulatory standards. Tube diameter, wall thickness, color coding, and surface texture may also be customized for identification, safety, or branding purposes. Tubing can be supplied in coils, cut sections, or assemblies with hose barbs, fittings, grommets, gaskets, or quick-connect couplings. Customization ensures optimal performance in applications ranging from laboratory fluid handling to heavy-duty hydraulic systems.

Types of Rubber Tubing

Rubber tubing comes in a diverse array of types, each suited for specific uses and performance requirements. Selecting the right tubing material is critical for ensuring longevity, safety, and cost-effectiveness in your application.

Latex Tubing

Latex tubing, derived from natural rubber harvested from the Pará tree, is prized for its superior flexibility, elasticity, and chemical inertness. This makes it ideal for laboratory, medical, surgical, and food processing applications. It’s commonly used for conductive rubber tubing, surgical tubing, and black rubber tubing. However, due to the risk of latex allergy, alternatives such as neoprene or silicone are preferred in healthcare and pharmaceutical environments.

Neoprene Tubing

Neoprene tubing is a synthetic rubber product known for its hypoallergenic properties, chemical resistance, abrasion resistance, buoyancy, and elasticity. It is often used for transporting liquids and gases in industrial, chemical, and marine applications, and as a protective insulation for wires and cables. Neoprene’s durability and cost-effectiveness make it a top choice for demanding environments.

PVC Rubber Tubing

PVC tubing (sometimes referred to as “vinyl rubber tubing”) is valued for its resistance to solvents, acids, alkalis, and its outstanding electrical insulation properties. Available in rigid or flexible formats and a variety of color options (including clear PVC), it is widely used in food and beverage processing, brewing, pool maintenance, wastewater management, and pharmaceutical manufacturing. PVC tubing is also favored for its affordability and ease of sterilization.

Silicone Tubing

Silicone tubing offers excellent elasticity, flexibility, and biocompatibility. Its smooth, non-reactive surface and resistance to heat, chemicals, weather, and water make it the preferred choice for medical devices, food-grade applications, peristaltic pumps, and high-temperature industrial processes. If you need tubing that remains flexible and functional across a broad temperature range or is suitable for autoclaving, silicone tubing is an optimal solution.

EPDM Tubing

EPDM (ethylene propylene diene monomer) tubing is a synthetic rubber prized for its resistance to heat, ozone, UV, and weathering. It is widely used in automotive, HVAC, and industrial systems for coolant, air, and vacuum lines. Its durability and cost-effectiveness make EPDM tubing a go-to for outdoor or harsh environment applications.

Viton Tubing

Viton tubing is a high-performance fluoroelastomer developed by DuPont for the aerospace industry. It offers unmatched resistance to fuels, chemicals, oils, and extreme temperatures. Viton tubing is essential in sectors where exposure to aggressive chemicals or high heat is routine, including chemical processing, automotive fuel systems, and pharmaceutical manufacturing.

Microbore Tubing

Microbore tubing, with its exceptionally small inner diameters, is engineered for precise fluid delivery in medical devices, analytical instruments, and laboratory settings. Its self-supporting structure and sterile, inert composition make it indispensable for intravenous lines and other sensitive medical procedures where accuracy and safety are paramount.

Metal Rubber Tubing

Metal rubber tubing, an innovative hybrid, integrates metal ions into a polymer matrix to create a flexible, lightweight material with exceptional resilience. It can withstand extreme cold, stretching, and chemical attack while retaining its original form. This tubing is ideal for aerospace, defense, and advanced industrial applications requiring both flexibility and durability.

Conductive Rubber Tubing

Conductive rubber tubing is formulated to dissipate static electricity and shield sensitive electronic equipment from electromagnetic and radio frequency interference (EMI/RFI). Available in conductive silicone and latex varieties, it is essential for use in cleanrooms, electronics manufacturing, and environments where static discharge could damage components or ignite flammable substances.

Sterilized Rubber Tubing

Sterilized rubber tubing is meticulously processed to remove contaminants through chemical sterilization, gamma irradiation, or dry heat. This ensures the tubing meets stringent hygiene requirements for use in medical, pharmaceutical, food, and biotech industries, where cleanliness and patient safety are critical.

Thermoplastic Rubber Tubing

Thermoplastic rubber tubing combines the properties of rubber and plastic, offering elasticity, abrasion resistance, and recyclability. Its flexibility and durability make it suitable for dynamic applications, including medical devices, pneumatic systems, and consumer products. If sustainability is a priority, thermoplastic rubber’s recyclability adds appeal for eco-conscious buyers.

Surgical Tubing

Surgical tubing is designed to meet strict medical standards for biocompatibility and sterility. Typically manufactured with thin walls to ensure unobstructed fluid passage, it is used in medical devices, catheters, and fluid transfer systems within hospitals and laboratories.

Black Rubber Tubing

Black rubber tubing is engineered for insulation and heat retention, making it suitable for HVAC, automotive, and industrial applications. Black nitrile rubber tubing, a popular variant, exhibits excellent resistance to oils, acids, and high temperatures, enabling its use in fuel lines, hydraulic systems, and chemical handling.

Hose Rubber Tubing

Hose rubber tubing, often reinforced with rigid rubber or metal wire, is designed for applications requiring structural integrity and pressure resistance. Common uses include garden hoses, industrial hoses for material handling, and pneumatic lines. Reinforced rubber tubing prevents kinking and collapse, ensuring uninterrupted flow even under demanding conditions.

Foam Tubing

Foam rubber tubing, though not intended for fluid conveyance, is widely used for cushioning, insulation, and ergonomic grips on tools and equipment. Its shock-absorbing properties make it ideal for packaging, medical devices, and consumer goods requiring comfort and protection.

Advantages of Rubber Tubing

Rubber tubing provides a multitude of advantages across industries:

- Affordability: Generally less expensive than plastic or metal tubing, with standard options starting below $10 per length. Even custom rubber tubing typically remains more cost-effective than metal alternatives.

- Versatility: Rubber tubing is available in a vast range of sizes, colors, materials, and properties, allowing manufacturers to meet both functional and aesthetic requirements for specific applications.

- Flexibility: Unlike rigid piping, rubber tubing can be routed through complex pathways, around obstacles, or in confined spaces—ideal for laboratories, manufacturing plants, and medical devices.

- Ease of Transport and Storage: Rubber tubing can be coiled, folded, or packaged in compact reels, reducing shipping and storage costs.

- Lightweight: Compared to metal, rubber and synthetic tubing are much lighter, minimizing structural load and simplifying installation.

- Low Maintenance: Simple cleaning protocols and resistance to many chemicals and environmental factors make rubber tubing easy to care for. For more information, see our section on Proper Care for Rubber Tubing below.

- Customization: Manufacturers offer extensive customization options, including wall thickness, reinforcement, color coding, branding, and pre-assembled fittings.

- Performance: Rubber tubing can be engineered to withstand extreme temperatures, high pressures, corrosive chemicals, and UV exposure, ensuring reliable performance in harsh environments.

Proper Care for Rubber Tubing

Proper maintenance extends the lifespan and ensures the safety of your rubber tubing, regardless of the application. Follow these best practices to maximize performance and minimize downtime:

Handling

Handle rubber tubing with care to prevent tears, abrasions, and punctures. Although some tubing is reinforced or coated for extra protection, all types benefit from gentle handling. Avoid dragging tubing on rough surfaces, tying it in knots, crushing it, or storing it under heavy objects. Store tubing elevated and protected from excessive moisture, dust, direct sunlight, and extreme heat to prevent premature degradation.

Usage

Always use rubber tubing according to its intended purpose. Using tubing outside its design parameters may cause corrosion, contamination, or structural failure. For instance, tubing rated for water may not be suitable for corrosive chemicals or high-pressure gases. If you have multiple application requirements, consult with your manufacturer or supplier for recommendations or custom solutions.

Cleaning and Inspection

Establish a regular maintenance schedule based on your supplier’s guidelines. Most rubber tubing can be cleaned with mild soap and water, then air dried. Always clean attachments, fittings, and connectors as well. Before cleaning, inspect tubing for cracks, leaks, discoloration, or signs of wear. Damaged sections should be replaced or, if possible, removed and reconnected using approved connectors. Regular inspections help prevent unplanned downtime and ensure continued safety.

Rubber Tubing Uses in the Concrete Sector

Rubber tubing is indispensable in the construction and concrete industries, where it facilitates efficient material handling, dust control, and process management. From transferring dry powders to managing liquid concrete, rubber tubing ensures productivity, safety, and compliance on job sites. Wondering how rubber tubing can improve your concrete production workflow? Explore these common applications:

Powder Discharge

In concrete batch plants and construction sites, robust rubber tubing is used for transferring dry bulk materials such as cement, sand, and concrete powder. These tubes are designed to withstand highly abrasive environments—often reinforced with special compounds to resist wear and prolong service life. Rubber tubing is essential for loading silos, transferring materials from storage bins, and unloading trucks, ensuring a continuous supply of raw materials for concrete mixing.

Dust Collection Ducts

Mixing and transporting dry concrete components generates significant dust, which can be hazardous to workers and the environment. Rubber tubing is a key component in dust collection duct systems, ensuring the safe and efficient removal of airborne particulates. Proper dust management reduces pollution, prevents respiratory illnesses, and helps facilities comply with OSHA and EPA regulations.

Concrete Placement

During concrete placement, rubber hoses and tubing are used to convey wet concrete from mixers to forms or molds. These tubes are engineered for flexibility, abrasion resistance, and high flow rates, enabling precise placement and reducing waste. Whether used for pumping concrete into foundations, slabs, or precast forms, high-quality rubber tubing ensures smooth, reliable operation under demanding conditions.

For more information on selecting abrasion-resistant, heavy-duty tubing for construction and concrete applications, compare top rubber tubing manufacturers now.

Rubber Tubing Standards

Industry standards for rubber tubing are essential to ensure safety, reliability, and regulatory compliance across a broad spectrum of sectors—including medical, automotive, industrial, food processing, and aerospace. Standards organizations such as ASTM International, ANSI, and ISO develop rigorous guidelines covering material properties, dimensional tolerances, performance, and testing procedures.

Key standards address critical considerations such as chemical and temperature resistance, pressure ratings, burst strength, and biocompatibility. For example, medical-grade tubing must meet USP Class VI or ISO 10993 standards for biocompatibility, while food-grade tubing is often certified to FDA or NSF requirements. Specialized tubing, such as explosion-proof or anti-static rubber tubing, must pass additional tests to certify safe operation in hazardous or flammable environments.

Non-compliance with these standards can have serious consequences, including equipment failure, safety incidents, product recalls, and legal liabilities. For manufacturers, failure to meet industry or regulatory standards can result in lost business, reputational damage, and costly litigation. For end-users, using non-compliant tubing increases the risk of workplace accidents, contamination, and costly downtime.

Adhering to established standards delivers peace of mind for buyers and end-users alike. Compliance ensures that tubing products have undergone extensive quality control, performance testing, and validation—delivering consistent, reliable results. For manufacturers, standards streamline production, improve product quality, facilitate market access, and differentiate their offerings in competitive bidding processes.

Looking for tubing that meets specific industry standards? Explore our rubber tubing manufacturer directory and filter by certifications such as ASTM, FDA, NSF, ISO, or custom requirements.

How to Choose the Right Rubber Tubing Manufacturer

Choosing a reliable rubber tubing manufacturer is crucial for ensuring product quality, regulatory compliance, and on-time delivery for your project. Here’s how to make an informed purchasing decision:

- Assess Experience and Expertise: Select manufacturers with a proven track record in your target industry—whether it’s medical, food and beverage, automotive, or industrial applications. Look for companies with relevant certifications and expertise in custom compounding or specialized tubing.

- Review Product Range: Ensure the supplier offers the specific tubing materials, sizes, and performance characteristics required for your application. Leading manufacturers will provide technical datasheets, samples, and engineering support to help you specify the optimal product.

- Request Certifications: Verify that the manufacturer’s products meet applicable industry standards and regulatory requirements (e.g., FDA, USP Class VI, NSF, ASTM). Request documentation and test reports as needed.

- Evaluate Production Capabilities: Consider whether the supplier can accommodate custom orders, value-added assembly, private labeling, or rapid prototyping. Advanced manufacturing capabilities ensure faster lead times and tailored solutions.

- Examine Quality Control: Strong quality management systems—such as ISO 9001 certification—are indicators of consistent product quality and traceability.

- Compare Pricing and Lead Times: Obtain detailed quotes from multiple manufacturers, factoring in unit cost, tooling fees, minimum order quantities, and shipping. Balance price with quality, support, and reliability.

- Check Customer Support: Responsive technical support, transparent communication, and after-sales service are essential for a successful partnership—especially for complex or mission-critical projects.

Ready to compare rubber tubing suppliers? Use our comprehensive manufacturer directory to browse company profiles, view specialties, and contact multiple suppliers through our streamlined RFQ (Request for Quote) system. Each listing features a profile page detailing the manufacturer’s core competencies, certifications, and a direct contact form for customized quotes or technical questions. Our patented website previewer also allows you to quickly assess manufacturers’ capabilities and match them to your unique project requirements.

Frequently Asked Questions About Rubber Tubing

- What is the best type of rubber tubing for medical applications? Silicone and latex tubing are popular for medical use due to their biocompatibility and flexibility. For allergy-sensitive environments, silicone is often preferred.

- Can rubber tubing be used for food and beverage transfer? Yes, food-grade rubber tubing (such as FDA-approved silicone, EPDM, or PVC) is widely used in food processing, brewing, and beverage dispensing applications.

- How do I determine the correct size of rubber tubing for my application? Consult with your supplier or use industry sizing charts to ensure you select tubing with the appropriate inner diameter, outer diameter, and wall thickness for your fluid type, pressure, and flow rate.

- What is the difference between natural rubber and synthetic rubber tubing? Natural rubber (latex) offers high elasticity and flexibility, while synthetic rubber (e.g., neoprene, EPDM, Viton) provides enhanced chemical resistance, temperature stability, and durability for specialized applications.

- How do I clean and maintain rubber tubing? Most rubber tubing can be cleaned with mild soap and water. For critical applications, follow your supplier’s recommended cleaning and sterilization protocols to prevent contamination and extend lifespan.

Still have questions about selecting, installing, or maintaining rubber tubing? Contact our expert manufacturers for personalized advice and technical support.

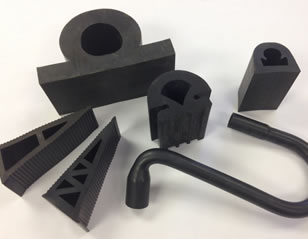

Rubber Extrusions

Rubber Extrusions Rubber Molding

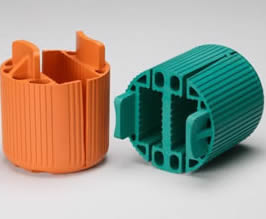

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

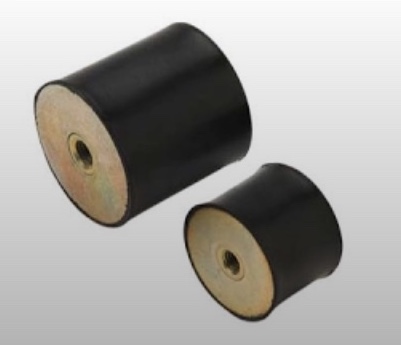

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services