Conductive rubber tubing is a versatile and highly useful material used in various industries, including electronics, automotive, aerospace, and medical.Its primary purpose is to provide electrical conductivity, grounding, and shielding.This article will discuss various methods used to create conductive rubber tubing, various types of conductive rubber tubing, and explain why a particular manufacturing method or type may be chosen. This article will subsequently discuss considerations regarding conductive rubber tubing, the benefits of conductive rubber tubing, and detail many applications of conductive rubber tubing.Read More…

As the largest in-house pure gum inventory carrier in the U.S., Atlantic Rubber Company has cost-effective and resilient rubber tubing. We carry a variety of materials so that we can make the best product for your needs.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber is your source for extruded, Molded, Die cut & Secondary fabrication work in rubber products, tubing and shapes made out of Silicone, Flurosilicone, Viton, Nitrile, Neoprene, EPDM, SBR,butyl & any custom compound. We offer our customers high quality, complex shapes and fast turn-around times.

Established in 1986, GSH Industries supplies plastic, aluminum and rubber tubing to an array of industries including automotive, consumer, marine and electrical.

More Conductive Rubber Tubing Manufacturers

Creating Conductive Rubber Tubing

Conductive rubber tubing is a specialized form of industrial tubing engineered to provide electrical conductivity while maintaining the inherent flexibility, durability, and resilience of rubber. The fabrication process begins with selecting the optimal base polymer, which may include natural rubber, silicone rubber, nitrile rubber, or other synthetic elastomers. The specific choice of base material is largely determined by the end-use requirements, such as temperature resistance, chemical compatibility, flexibility, and cost-effectiveness.

To impart electrical conductivity, the rubber compound is blended with conductive fillers. Carbon black is the most prevalent additive due to its cost efficiency, processability, and strong conductive properties, making it popular for conductive tubing applications across electronics, automotive, and industrial sectors. Other conductive agents include graphite, metallic powders (such as silver, nickel, copper, or aluminum), and in some high-performance applications, carbon nanotubes or conductive polymers.

The conductive filler is incorporated into the rubber matrix using precision mixing equipment, ensuring uniform dispersion for consistent conductivity throughout the finished conductive rubber hose or tubing. The final compound is then shaped and cured using methods such as extrusion or molding, creating a robust, long-lasting product ready for demanding commercial, industrial, or technical applications.

Looking for a guide on how to choose the right conductive rubber material for your project? Explore our resources below or reach out to our network of conductive rubber tubing manufacturers for expert advice.

Methods to Produce Conductive Rubber Tubing

Manufacturing conductive rubber tubing involves several well-established techniques. The most commonly used methods are:

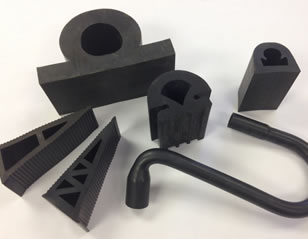

- Extrusion: The rubber compound is forced through a specially designed die under controlled pressure and temperature, producing continuous lengths of conductive tubing with precise inner and outer diameters. This method is ideal for high-volume production and applications requiring consistent wall thickness and flexibility.

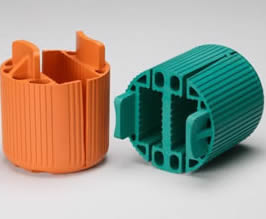

- Compression Molding: Pre-measured amounts of conductive rubber are placed in a heated mold, then compressed under pressure to form the desired tube profile. This method is suitable for manufacturing thicker, more complex, or custom-shaped conductive tubes, such as gaskets or seals with integrated conductive pathways.

- Injection Molding: The conductive rubber is heated and injected into a closed mold cavity, enabling the rapid production of intricate shapes or multi-component assemblies where tight tolerances and repeatability are critical.

How do you decide which production method is right for your application? Factors influencing the choice include:

- Volume Requirements: Extrusion is preferred for large runs, while molding is better for custom or lower-volume products.

- Product Complexity: Molding methods accommodate complex geometries, integrated connectors, or over-molded features.

- Performance Specifications: Considerations such as desired conductivity level, mechanical strength, and thermal resistance may dictate the most suitable process.

- Cost and Lead Time: Extrusion typically offers lower per-unit costs for simple tubing, while molding processes may have higher tooling costs but deliver precision for advanced designs.

Our conductive tubing resource center can help you compare methods and find a supplier that matches your production, prototyping, or R&D needs.

Types of Conductive Rubber Tubing

There is a broad spectrum of conductive rubber tubing types to suit diverse performance requirements and environmental conditions. Key categories include:

- Silicone Conductive Tubing: Offers outstanding temperature resistance (up to 200°C or higher), flexibility, and chemical inertness. Commonly used in medical devices, high-temperature electronics, and cleanroom environments where both conductivity and biocompatibility are required.

- Fluorosilicone Conductive Tubing: Combines the electrical properties of conductive fillers with enhanced resistance to fuels, oils, and aggressive chemicals. Ideal for aerospace, automotive, and chemical processing industries.

- EPDM (Ethylene Propylene Diene Monomer) Conductive Tubing: Known for its excellent resistance to weathering, ozone, UV, and outdoor exposure. Well-suited for outdoor electrical enclosures, automotive and solar applications. Learn more about EPDM conductive tubing here.

- Nitrile Conductive Tubing: Provides good oil and fuel resistance, making it suitable for automotive fuel lines, hydraulic systems, and industrial equipment where static dissipation is required.

- Custom Multi-Layer or Co-Extruded Tubing: Combines conductive and non-conductive layers to create tubing with tailored electrical, mechanical, and chemical properties for specialized applications.

Wondering which type of conductive rubber tubing best matches your application? Use our selection guide or consult directly with our vetted manufacturers for recommendations based on your specifications.

Considerations Regarding Conductive Rubber Tubing

While conductive rubber tubing offers many technical advantages, several important factors should be weighed during the selection and purchasing process:

- Health and Safety: Some conductive additives (such as fine metal powders or carbon black) can pose health risks during manufacturing due to inhalation or skin contact. Finished tubing is generally safe, but proper handling and disposal protocols must be followed.

- Environmental Impact: The disposal of synthetic rubbers and conductive fillers can have environmental implications. Consider options for recycling, reclaiming, or choosing eco-friendly materials when possible.

- Regulatory Compliance: Depending on the application (medical, food processing, aerospace), tubing may need to meet specific industry standards such as RoHS, REACH, FDA, or ASTM specifications.

- Performance Degradation: Over time, exposure to harsh chemicals, UV radiation, or extreme temperatures may affect the tube’s conductivity or mechanical integrity. Selecting the proper formulation ensures long-term reliability.

- Cost versus Performance Trade-Offs: High-performance fillers (e.g., silver or carbon nanotubes) increase costs but deliver superior conductivity. Balance your application’s requirements with your budget.

Looking for advice on safe handling, compliance, or sustainability in conductive tubing? Visit our compliance resources or request support from our regulatory specialists.

Benefits of Conductive Rubber Tubing

Conductive rubber tubing is engineered to deliver unique benefits for demanding industries and critical applications. The key advantages include:

Electrical Conductivity

Provides reliable electrical grounding and shielding to protect sensitive equipment from static discharge and electromagnetic interference (EMI). Essential for maintaining signal integrity in electronics, preventing arcing, and reducing the risk of component failure.

Flexibility & Customization

Retains the natural flexibility and elasticity of rubber, allowing for complex routing, tight bends, and robust sealing in confined enclosures or moving assemblies. Custom formulations and dimensions are available to meet exact project needs.

Durability & Longevity

Resists wear, abrasion, and mechanical fatigue, even in demanding industrial or outdoor environments. Many conductive rubber compounds maintain their properties over years of continuous use, reducing maintenance and replacement costs.

Temperature Resistance

Performs consistently across a wide temperature range, from sub-zero cold to extreme heat. High-temperature silicone and fluorosilicone versions are especially valued in aerospace, automotive, and industrial processing applications.

Chemical and Environmental Resistance

Effectively withstands exposure to oils, fuels, acids, solvents, ozone, and UV, depending on the base polymer. This ensures suitability for harsh chemical processing, laboratory, and outdoor installations.

Static Dissipation & Anti-Static Properties

Actively dissipates static electricity, reducing the risk of sparks, explosions, or equipment damage in environments where flammable gases, dust, or sensitive electronics are present. Also used in electrostatic discharge (ESD) control systems.

Ease of Processing & Integration

Compatible with standard fabrication techniques, including extrusion, molding, and die-cutting. Easily integrated with fittings, connectors, and assemblies to streamline manufacturing and simplify installation.

Regulatory & Industry Compliance

Customizable to meet a wide array of industry regulations, including RoHS, REACH, FDA, and MIL-SPEC standards. Reliable performance in mission-critical applications is supported by stringent quality control and traceability.

Have questions about the value of conductive rubber tubing for your specific use case? Browse our application library or submit your requirements for a personalized assessment.

Applications of Conductive Rubber Tubing

Thanks to its unique combination of electrical, chemical, and mechanical properties, conductive rubber tubing is used in a multitude of industries and scenarios. Typical applications include:

Electronics & Electrical Engineering

Conductive tubing is widely utilized for EMI/RFI shielding, static discharge protection, and grounding in electronic devices, computer peripherals, and telecommunications equipment. It is also a preferred solution for flexible circuitry, sensor housings, and high-reliability connectors.

Automotive & Transportation

In the automotive sector, conductive rubber hoses and tubing are integral to fuel delivery systems, battery protection, and hybrid/electric vehicle components. They help prevent static build-up, shield sensitive electronics, and provide weatherproof seals in harnesses and connectors.

Aerospace & Defense

Aerospace engineers rely on conductive rubber tubing for vibration isolation, EMI shielding, and static dissipation in avionics, satellite, and defense systems. The material’s ability to withstand extreme temperatures and environmental stressors is critical in these high-stakes applications.

Medical & Healthcare

Medical device manufacturers use conductive silicone tubing for electrodes, biosensors, and patient monitoring systems, ensuring accurate signal transmission and patient safety. Anti-static medical tubing is also used in operating rooms, laboratories, and pharmaceutical processing.

Robotics & Automation

Robotics often require flexible, conductive tubing for cable management, sensor integration, and actuator connections. The material’s flexibility and electrical properties enable precise motion control and reliable system feedback.

Industrial Equipment & Process Control

Industrial automation systems use conductive tubing for static-safe conveyor belts, rollers, and pneumatic lines. It is also a key component in hazardous material handling, bulk powder transfer, and cleanroom environments.

Consumer Electronics & Wearable Devices

From smartwatches and fitness trackers to game controllers and touch-sensitive devices, conductive tubing ensures effective signal transmission and static protection. Its comfort and flexibility make it ideal for wearable technology.

Semiconductor & Cleanroom Applications

Cleanroom-grade conductive rubber tubing is essential for static control in semiconductor manufacturing and precision assembly lines, where even minor discharges can cause costly defects.

Other Specialized Uses

Additional applications include laboratory equipment, ESD-safe workstations, fuel cell systems, and scientific research devices. Custom-engineered solutions are available for virtually any scenario where static control, electrical shielding, or robust environmental protection is required.

Searching for application-specific guidance or case studies? Explore our in-depth industry pages or connect with technical experts for tailored recommendations.

How to Choose the Right Conductive Rubber Tubing Manufacturer

Selecting a reliable conductive rubber tubing supplier is essential for achieving performance, safety, and compliance in your project. Here are key decision factors to consider:

- Technical Capabilities: Evaluate manufacturers’ expertise in formulating and processing conductive compounds, including their ability to meet custom specifications for conductivity, dimensions, and performance.

- Quality Assurance: Confirm adherence to industry certifications, quality management systems (ISO 9001, ISO 13485), and traceability protocols for peace of mind in critical applications.

- Production Capacity: Ensure the supplier can meet your order volume, lead time, and delivery requirements—whether for prototyping, short runs, or high-volume manufacturing.

- Regulatory Compliance: Verify the supplier’s track record in providing RoHS, REACH, UL, FDA, or military-grade compliant tubing as needed for your industry.

- Customer Support & Collaboration: Choose a partner willing to provide technical support, prototyping, and rapid turnaround for development projects.

- Cost & Value: Assess total cost of ownership, including price, durability, and after-sales service. Sometimes a higher upfront investment delivers better long-term reliability and reduced downtime.

To ensure you have the most productive outcome when purchasing conductive rubber tubing, compare several companies using our comprehensive directory of conductive rubber tubing manufacturers. Each manufacturer’s business profile highlights core competencies, experience, and unique capabilities. Use our contact forms to request detailed technical information, obtain a quote, or schedule a consultation.

Take advantage of our patented website previewer to quickly review each company’s specialties, or streamline your vendor search by submitting a single RFQ to multiple suppliers.

Ready to get started? Compare top conductive rubber tubing manufacturers or request a quote today to receive personalized recommendations based on your application, budget, and technical requirements.

Frequently Asked Questions About Conductive Rubber Tubing

- What is conductive rubber tubing used for? Conductive rubber tubing is designed for static control, EMI shielding, electrical grounding, and signal transmission in industries such as electronics, automotive, aerospace, medical, and industrial automation.

- How do I specify the right level of conductivity for my application? Work with your supplier to define the required volume resistivity (typically in ohm-cm), desired shielding effectiveness, and environmental factors. Custom formulations are available for ESD, EMI, or low-resistance grounding uses.

- Can conductive tubing be made in custom shapes or sizes? Yes, manufacturers offer custom extrusion and molding services to meet demanding dimensions, shapes, colors, and performance characteristics.

- Is conductive rubber tubing safe for food or medical applications? Food-grade and medical-grade formulations are available, made with FDA-compliant or biocompatible materials. Always check certifications and documentation with your supplier.

- What is the typical lifespan of conductive rubber tubing? With proper material selection and installation, conductive tubing can last several years even in harsh conditions. Regular inspection and maintenance are recommended in critical environments.

- How can I compare prices and lead times among suppliers? Use our RFQ tool or contact forms to easily request quotes from multiple vetted manufacturers, ensuring you receive competitive offers tailored to your requirements.

For more detailed answers or to discuss your specific project, contact our technical support team or consult our knowledge base for in-depth guides, whitepapers, and case studies.

Rubber Extrusions

Rubber Extrusions Rubber Molding

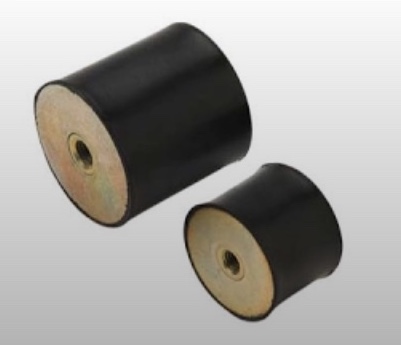

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services